Since 2007, Pesa has been

part of the Bizerba Group - a

global technology supplier for

professional system solutions

in weighing, information and

food service technology that

leads the market in many areas.

In the field of logistics and intra-

logistics, together we can realise

complete concepts and technologies

covering all aspects of conveying,

storage, picking, sorting and

labelling, including comprehensive

control and software applications.

- ... Practical globalisation ...

... Pesa 2-string technology ....

There is only one way of reliably eliminating gravitation forces: It must be possible to compare the unknown mass with a known reference mass. Both masses are then insensitive to acceleration but to the same extent, which means that the comparison will deliver uncorrupted mass results anywhere in the world.

Thanks to the mass comparison system patented by, 2-string digital mass encoders are also approved for calibratable operations with inclinations of up to 10 %. In addition, calibratable multi-range and multi-interval applications can also be realised with Pesa 2-string digital mass encoders - without the need to change any settings.

Weighing via hybrid mass measurement

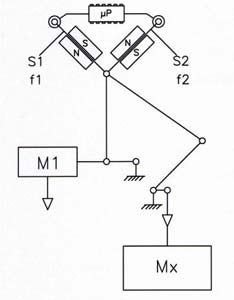

With Pesa 2-string digital mass encoders, the force being measured is reduced via levers, a parallelogram or membranes so that the load is then applied to the actual weighing cell. There, the tensile force of the string caused to vibrate by an excitation current in a magnetic field, changes. The frequency change in turn creates a digital measured weight value. Supplemented by an integrated CPU, software and interfaces, the extremely compact sensor delivers its weight values directly to an industrial controller, a PC or a display. The signal, with an internal resolution greater than 1,600,000 (ppm), is transmitted digitally - completely without A/D conversion - and with a signal yield greater than 20 %.

2-string technology

These are good reasons why Pesa 2-string digital mass encoders and weighing modules are used in a wide range of applications:

in measuring ranges from 100 g to 1,500 kg and in weighing platforms for up to 6,000 kg.

2-string digital mass encoder

The Pesa 2-string digital mass encoder is based on a few (but high quality) individual parts that, after installation, work with precision for many years and without the need for servicing. The principle of mass measurement reduces acceleration-related influences of that type that occur on conveyor lines on platforms. Even asymmetrical load distributions on in-motion scales have next to no negative influence on the measurement results. Adaptation to various areas of use is also made possible with the aid of the mechanical parallelogram technology. There are no complications at all should you wish to adjust the same platform to suit different load ranges, the large weighing platform of the load carrier permitting maximum weighing belt dimensions.